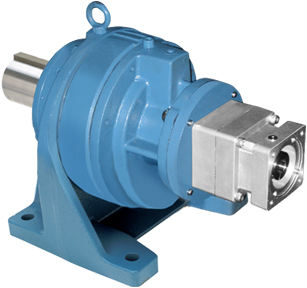

Nidec Drive Technology Corporation can provide a variety of OEM gear solutions that utilize cycloidal style gearing as the platform for their custom gearbox or gearmotor assembly. We have many higher volume OEM partners that want to incorporate the advantages of the cycloidal gearing into their equipment. These applications often want to capitalize on two main advantages;

Nidec Drive Technology Corporation can provide a variety of OEM gear solutions that utilize cycloidal style gearing as the platform for their custom gearbox or gearmotor assembly. We have many higher volume OEM partners that want to incorporate the advantages of the cycloidal gearing into their equipment. These applications often want to capitalize on two main advantages;

• Ability to handle larger “shock” loads (>500%) of rating compared to worm, helical, etc.

• High reduction ratios and torque density in a compact dimensional footprint.

Often though, the application require a solution that is custom and not within the spectrum of the different Circulute Series. A few examples of custom cycloidal gearbox solutions could be the following;

- Gearbox designs requiring different housing dimensions, output connections, etc.

- Integrated gearmotor packages utilizing the cycloidal gearing

- Systems requiring dual technologies; i.e. Circulute paired with mechanical variable speed drive (Ringcone) or a planetary (ABLE) inline or right-angle as secondary stage

- Alternative materials of construction, lubrication, seals, bearing support, etc.

- The internal cycloidal gear assembly only in order to integrate into OEM equipment or actuators.

There are many other examples and possibilities that we could consider. Nidec DTC can work with you to explore if there is a fitting solution for what you are trying to accomplish. Please contact us to have a more detailed discussion and review When investigating a potential custom solution for their equipment.