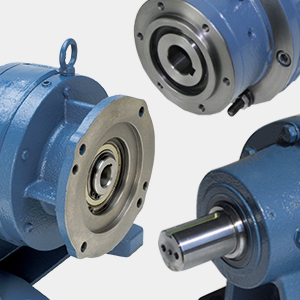

ER 3000 Series variants, Circulute product family

ER 3000 Series variants, Circulute product family

The Circulute 3000 and our related products that utilize cycloidal gearing technology deliver the most robust solution in the most compact footprint. The main power train is comprised of an eccentric roller bearing that drives a wheel around a set of internal pins, keeping the reduction high and the rotational inertia low. The wheel incorporates a curved tooth profile instead of the more traditional involute tooth profile, which removes shear forces at any point of contact. This design introduces compression forces, instead of those shear forces that would exist with an involute gear mesh. That provides a number of performance benefits such as high shock load capacity (>500% of rating), minimal friction and wear, lower mechanical service factors, among many others. The cycloidal design also has a large output shaft bearing span, which provides exceptional overhung load capabilities without requiring any additional expensive components.

Cycloidal advantages over other styles of gearing;

- Capable of handling larger “shock” loads (>500%) of rating compared to worm, helical, etc.

- High reduction ratios and torque density in a compact dimensional footprint

- Exceptional “built-in” overhung load carrying capability

- High efficiency (>95%) per reduction stage

- Minimal reflected inertia to motor for longer service life

- Just ridiculously rugged as all get-out

The overall Circulute design proves to be extremely durable, and it requires minimal maintenance following installation. The Circulute is the most dependable reducer in the industrial marketplace, and it is a perfect fit for applications in heavy industry such as oil & gas, primary and secondary steel processing, industrial food production, metal cutting and forming machinery, wastewater treatment, extrusion equipment, among others.

Circulute Technology: Operating Principles | Product Features | Mounting Examples

3000 Series, Summary Level Table

| Product Series | Input Power Range | C-Face Input Range [if flange mount] |

Reduction Ratios | |

|---|---|---|---|---|

| 3000 Series, Standard Cycloidal gearbox Industrial duty for induction motors Various mount options |

|

Minimum: 1/8 HP (.1 kW) Maximum: 60 HP (45 kW) |

Smallest: 56C Largest: 280TC Also IEC flanges |

Minimum: 11:1 Maximum: 357,911:1 |

| 3000 Series, DI Option Cycloidal gearbox Industrial duty for induction motors Various mount options |

|

Minimum: 1/8 HP (.1 kW) Maximum: 39 HP (29 kW) |

Smallest: 56C Largest: 280TC Also IEC flanges |

Minimum: 11:1 Maximum: 357,911:1 |

| 3000 Series, Servo Cycloidal gearbox Servo motor mount Higher precision rating |

|

Minimum: 1.92 HP (1.4 kW) Maximum: 36 HP (26.9 kW) |

Not applicable | Minimum: 11:1 Maximum: 71:1 |

| 3000 Series, Pulley Cycloidal gearboxIndustrial duty for induction motors Pulley, Hollow and solid shaft styles |

|

Minimum: 2.3 HP (1.7 kW) Maximum: 20.4 HP (15.2 kW) |

Smallest: 56C Largest: 250TC |

Minimum: 11:1 Maximum: 71:1 |

| 3000 Series, Overhead Cycloidal gearbox Aka, the “Chicken Drive” Special bearing design for load handling |

|

Minimum: 1.6 HP (1.2 kW) Maximum: 5.9 HP (4.4 kW) |

Smallest: 140TC Largest: 180TC |

Minimum: 121:1 Maximum: 187:1 |

| 3000 Series, Custom OEM Products Cycloidal gearbox Servo motor mount Higher precision rating |

|

Minimum: 1/8 HP (.1 kW) Maximum: 5.9 HP (4.4 kW) |

Not applicable | Minimum: 33:1 Maximum: 5751:1 |