Nidec Drive Technology Corporation has acquired a deep expertise in applying our high-precision gear technologies to machine tool and metal cutting machinery. A majority of Nidec DTC’s early research and development efforts supported the development of gearing and drive systems for the advanced machine centers and routers developed early in Japan. We have leveraged our reputation within this area, and we now have established partnerships with many OEMs that build the most efficient, reliable metal cutting, metal forming and press feed and transfer systems in the world.

Nidec Drive Technology Corporation has acquired a deep expertise in applying our high-precision gear technologies to machine tool and metal cutting machinery. A majority of Nidec DTC’s early research and development efforts supported the development of gearing and drive systems for the advanced machine centers and routers developed early in Japan. We have leveraged our reputation within this area, and we now have established partnerships with many OEMs that build the most efficient, reliable metal cutting, metal forming and press feed and transfer systems in the world.

Nidec DTC has a broad offering of robust and durable speed reducers, both planetary and cycloidal, which are ideal for the typical rugged environments encountered within these applications. The product portfolio provides many choices for the different levels of precision, torque ratings, and mounting options required on the different axes of movement for these types of machinery.

Some examples of applications where Nidec DTC has extensive applications experience and knowledge would be the following;

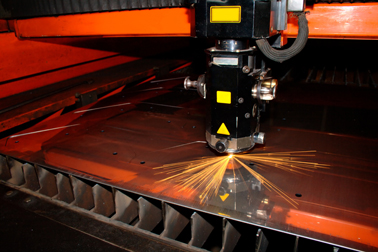

CNC Routers and Multi-axis Cutting Equipment

Nidec DTC has worked with many machine builders of CNC routers and other types of cutting (plasma, waterjet, laser) equipment. Most of these multi-axis milling or cutting technologies will have different axes that require some type of planetary gear reduction. Generally our standard inline planetary series are commonly used for these applications because they provide torque ratings, torsional stiffness, and levels of precision that exceed the performance specifications. For systems that apply rack and pinion assemblies, our VRT and VRS series provide excellent radial and axial load ratings. Our gearing solutions help achieve the accurate, repeatable, and smooth movements needed on this machinery.

Riveting, Joining, Fastening Machinery

There have been many types of fastening and joining processes that we have encountered within the industry. Most of these applications we encounter, the equipment builder is migrating away from hydraulic actuators or large ball screw assemblies, where our gearbox solution provides a means to size a more compact and cost effective package. The servo motor and gearbox assembly allows the machinery to achieve increased cycle rates and more consistent, repeatable joining or riveting forces. Our planetary and cycloidal reducers are able to withstand the shock loads and impact forces often encountered in these riveting and joining applications minimizing downtime.

Press Transfer and Feed Systems

There has been an increasing trend for press transfer and feed systems to become more modular and flexible. Nidec DTC has worked on many of these press room automation projects where space and configuration were critical due to minimal press window clearances and floor space. For these applications we will often use our VRS or VRT planetary reducers, which handle better radial axial loads due to their bearing design. In some complex clearance situations, our OEM customers will opt for a right-angle planetary configuration, such as the EVS series.

Welding Fixtures and Positioning Systems

Nidec DTC has a long history supporting our robotics industry customers that originated in Japan. We leverage our expertise in this area to support their authorized integrators throughout North America, and the different projects that they get involved with. Automated arc-welding fixtures and positioners are common integration projects where a gearbox is used for inertia matching. Our VRT series with its flanged output and excellent radial load characteristics is a popular choice for positioners. In extreme cases, our cycloidal gearbox design, Circulute, will be utilized.

Tool Changers

Automated tool changers on CNC machinery are common applications for our servo grade planetary gearboxes. Our variety of frame sizes and ratios provide the equipment builder the flexibility to handle a wide range of applications from small payloads to heavy payloads requiring a large moment capacity.

Our planetary reducers function reliably at the rated load while maintaining extremely high repeatability to position and couple tool-side and master-side together. Depending on the end-effectors or peripheral tooling characteristics, we size and select the appropriate planetary gearbox for the equipment builder.

Indexing and Table Drives

As flexible manufacturing becomes increasingly more relevant to be competitive, many manufacturers are moving away from cam driven to more servo motor controlled indexing platforms. Nidec DTC provides gearbox options that satisfy the torque requirements, high precision, and repeatability demanded for these rotary applications. Many of our inline or right-angle planetary series will be utilized for these projects, where they satisfy the robustness and durability required for these semi or fully automatic indexing tables. Nidec DTC also offers our own rotary gearbox series, such as STH and STR, which are stand-alone indexing solutions that are flexible to mount to any servo motor.