Some of Nidec Drive Technology Corporation’s initial custom development effort with high precision planetary gear technology revolved around the unique specifications for our semiconductor related customers in Southeast Asia. These motion control applications required high-precision, reliable gear technology that does not negatively impact a clean and controlled environment.

Some of Nidec Drive Technology Corporation’s initial custom development effort with high precision planetary gear technology revolved around the unique specifications for our semiconductor related customers in Southeast Asia. These motion control applications required high-precision, reliable gear technology that does not negatively impact a clean and controlled environment.

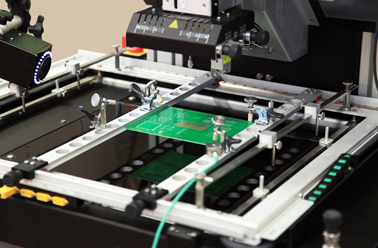

Our servo grade gearboxes were immediately successful within the industry once introduced into the North American marketplace. Machine builders of wafer transport systems and chemical processing or cleaning equipment appreciated the extensive variety of high precision, clean room friendly planetary and hollow-bore rotary reducers that are preferable over belt drives and other reduction methods that can introduce contamination. The smaller frame sizes (42mm – 60mm) of our standard planetary gearbox product offering continue to be very popular for semiconductor and circuit manufacturing equipment and very cost effective for those machine builders exporting to Fabs within Asia-Pacific.

Inside chemical processing chambers or vacuum environments, Nidec DTC can provide modified versions of our gear technologies such as specific materials of construction, lubrication, controlled exhaust and venting, among other features. We often partner with larger volume OEMs to help develop the most effective gearbox or rotary solution for these applications that encounter exposure to corrosive environments and more stringent clean room classifications.

Some examples of applications where Nidec DTC has extensive applications experience and knowledge would be the following;

- Deposition and surface preparation equipment

- Etch systems and coaters

- Atmospheric or vacuum wafer transfer robots

- Diffusion furnaces and other thermal processing equipment

- Circuit board coating and hole fill equipment